Pioneering, Award Winning

‘Non-Stick’ Glass Surface Treatment

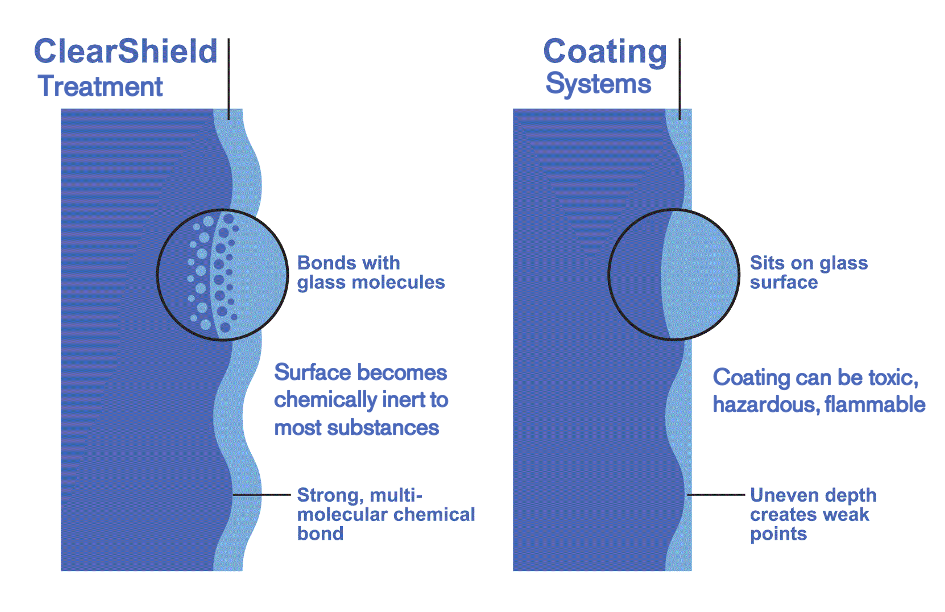

ClearShield is NOT a coating, it is a unique polymeric resin treatment that becomes part of the glass.

Forms a permanent highly cross-linked multi -molecular bond with the glass modifying and transforming the entire glass surface.

Glass is subjected to a corrosion process caused by reactions between the glass surface and organic and inorganic pollutants contaminating the surface making the glass difficult to clean.

Clearshield glass treatment solves this problem by forming an even <1u thick protective layer following the contours of the glass, creating a tough, smooth, hydrophobic surface. It is completely transparent, chemically inert, and UV stable. It will not chip, crack, peel or change colour.

The ONLY glass surface treatment that is non toxic and non hazardous.

Reduce Maintenance Costs. Professionals choice for long term low maintenance.

ClearShield resists limescale build-up, water spotting and dirt pickup.

Resisting contamination build- up maintains a pristine appearance for longer and makes the glass surface easier to clean.

Significant reduction in maintenance window / glass cleaning costs particularly for high rise commercial buildings. (by ~50% = large cost savings).

Graffiti is more easily removed and glass retains its hydrophobic properties.

Resists adhesion and growth of bacteria/fungi creating a more hygienic environment.

ClearShield helps glass maintain its original light transmittance (t-Value), reduces energy requirements, operating costs and environmental impacts such as CO2 emissions by half, makes glass “green” in performance.

Protects against corrosive Salt Spray. 1000 hours of continuous testing.

We commissioned an independent experiment to put ClearShield Glass to the test in brutal conditions. Placed in an Acetic Salt Spray Cabinet for 1000 hours continuous exposure to assess its durability and make a comparison with regular glass.

A ClearShield Glass panel and an untreated glass panel were exposed to an Acetic Acid Salt Spray Test (AS2331.3.2). The samples were placed at the bottom of the cabinet to ensure run-off from other metallic test samples dripped onto both panels, maximising pick-up of corrosion and salt deposits. After 1000 hours both panels were removed and rested for 24 hours at ambient temperature. Reverse sides were cleaned with warm soapy water and photos taken.

Test conducted by R&D Technical Services: Dulux Powder & Industrial Coatings, Glenfield

Remove paint easily. Tested resistance to graffiti on treated glass.

We commissioned experiment to put ClearShield Glass under the test with Spray Paint direct exposure to assess its durability and make a comparison with regular glass.

A ClearShield Glass panel and an untreated glass panel were exposed to over the counter Spray Paint. The samples were placed in open environment to ensure drying an atmospheric pollutants to maximise adhesion. After 48 hours both panels were removed and rinsed with cold water then and then a plastic scraper was used to remove surface paint. The removal of the paint from the ClearShield treated panel was easy and the panels retained its hydrophobic properties. The untreated glass panel glass pores retained spray paint particles even after heavy chemical usage to remove paint.

Test conducted by R&D Technical Services: